Mercedes glass sensor calibration is vital for modern car safety systems like adaptive cruise control and automatic emergency braking. Regular post-calibration tests are crucial to prevent misaligned readings, ensuring sensors accurately detect environmental cues. These tests involve specialized tools and manual inspections, with computer scans confirming optimal performance within manufacturer specifications. Maintaining precise calibration through testing prevents safety hazards and operational inefficiencies, facilitating seamless vehicle ownership and repair experiences.

In ensuring peak performance and safety, regular post-calibration tests for Mercedes glass sensors are paramount. These sensors play a critical role in modern vehicle technology, from adaptive cruise control to lane-keeping assist. This article delves into the significance of calibrating Mercedes glass sensors, explores effective testing methods and tools, and provides insights on interpreting results to guarantee optimal sensor accuracy. By understanding these processes, owners can maintain their vehicles’ advanced driver assistance systems (ADAS) functionality for safer driving experiences.

- Understanding Mercedes Glass Sensor Calibration Importance

- Post-Calibration Testing Methods and Tools

- Ensuring Optimal Performance: Interpretation of Results

Understanding Mercedes Glass Sensor Calibration Importance

Mercedes glass sensor calibration plays a pivotal role in ensuring the safety and reliability of modern automobiles. These sensors are integral components of advanced driver-assistance systems (ADAS), responsible for tasks like adaptive cruise control, lane keeping, and automatic emergency braking. Accurate sensor readings are crucial for these systems to function optimally, enabling vehicles to navigate roads intelligently and respond to potential hazards promptly.

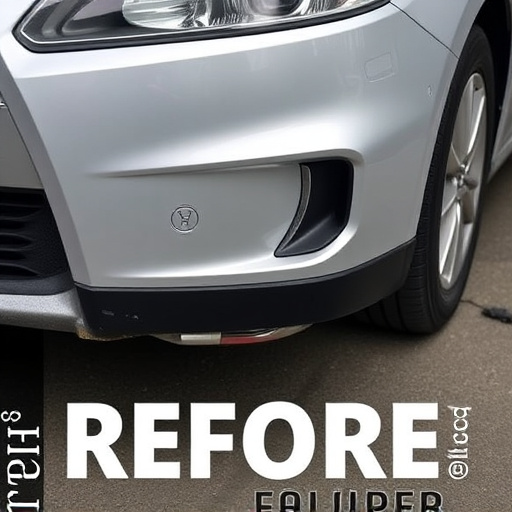

Proper calibration guarantees that the glass sensors accurately detect and interpret environmental cues, such as changes in weather conditions or road markings. In the event of a car restoration or auto glass repair, it’s even more critical to ensure these sensors are precisely calibrated. This is because any misalignment or deviation in sensor readings can lead to catastrophic failures in safety-critical systems, highlighting the importance of regular post-calibration tests for Mercedes glass sensors as part of routine maintenance at an auto collision center or during auto glass repair services.

Post-Calibration Testing Methods and Tools

Post-calibration testing is an essential step to ensure the accuracy and reliability of Mercedes glass sensors. Several advanced methods and tools are employed in this process, designed to detect even the slightest deviations from ideal performance. One common technique involves using specialized measurement devices that can precisely gauge the sensor’s response time and sensitivity after calibration. These devices simulate various environmental conditions, such as temperature fluctuations and light intensity changes, to assess how well the sensor maintains its accuracy under different circumstances.

Additionally, visual inspections and manual checks are crucial components of post-calibration tests. Technicians examine the glass sensors for any visible damage or debris that could affect performance, common issues like cracks or chips in the sensor’s housing are promptly addressed during this phase. Furthermore, auto body services often incorporate computer diagnostic scans to cross-reference the sensor’s output with expected readings, ensuring it functions optimally and aligning with the manufacturer’s specifications, especially when considering hail damage repair or auto glass repair scenarios.

Ensuring Optimal Performance: Interpretation of Results

Maintaining peak performance is paramount when it comes to Mercedes glass sensors, and post-calibration tests are a critical component in achieving this goal. After calibrating the sensor, interpreting the test results becomes an art. Each reading should be carefully analyzed to ensure the sensor operates within the specified tolerance levels. These tests not only verify the accuracy of the sensor but also pinpoint any potential discrepancies or drift over time, which is crucial for maintaining the vehicle’s safety and operational efficiency.

Understanding the outcomes of these tests requires a nuanced approach. If the results fall within the acceptable range, it confirms that the sensor is functioning optimally. However, any deviations should not be overlooked. Identifying and addressing issues early can prevent more complex problems, especially in sophisticated systems like Mercedes glass sensors. Regular post-calibration checks, alongside prompt repairs for any detected anomalies, are key to ensuring a seamless experience for both vehicle owners and auto repair professionals alike, whether it’s a simple dent repair near me or a more intricate paintless dent repair process.

Post-calibration testing is an essential step in ensuring the accuracy and reliability of Mercedes glass sensors. By utilizing advanced tools and interpreting results meticulously, vehicle owners can guarantee optimal performance and precise measurements. Regular post-calibration checks are vital to maintaining the integrity of sensor data, especially in the dynamic automotive industry where precision and safety go hand in hand. This process empowers folks to make informed decisions regarding their Mercedes glass sensor calibration, ultimately enhancing overall driving experience and vehicle efficiency.